Best Price on Cold Drawn Tube Process - Steel Pipe Processing – XUANZE

Best Price on Cold Drawn Tube Process - Steel Pipe Processing – XUANZE Detail:

The pin shaft is a kind of standardized fastener, which can be statically fixed and connected, or can move relative to the connected part. It is mainly used for the hinge joint of two parts to form a hinge connection. The pin shaft is usually locked with a split pin, which is reliable in work and easy to disassemble.

The ASTM standard stipulates that the tensile strength of 1040 steel is 600MPa, the yield strength is 355MPa, the elongation is 16%, the reduction of area is 40%, and the impact energy is 39J .

1040 steel is a common material for shaft parts and is widely used in mechanical manufacturing. This steel has good mechanical properties and is cheap. But this is a medium carbon steel, and its quenching performance is not good. 1040 steel can be hardened to HRC42~52. Therefore, if the surface hardness is required and the superior mechanical properties of 1040 steel are desired, the surface of 1040 steel is often quenched (high-frequency quenching or direct quenching) to obtain the required surface hardness.

Alloy structural steel such as 5140 is suitable for shaft parts with medium precision and high speed. After quenching and tempering and quenching, this kind of steel has better comprehensive mechanical properties.

5140 steel is one of the most widely used steels in machinery manufacturing. After quenching and tempering, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity. The hardenability of steel is good. It can be hardened to Ф28~60mm in water quenching and Ф15~40mm in oil quenching. In addition to quenching and tempering, this steel is also suitable for cyanidation and induction hardening. The cutting performance is better. When the hardness is HB174~229, the relative machinability is 60%.

4130 steel is a low-alloy ultra-high-strength steel. After heat treatment, it has good comprehensive mechanical properties, high strength, sufficient toughness, hardenability, weldability, and processing and formability, but it has low corrosion resistance and oxidation resistance. It is used after low temperature tempering or austempering.

4140 steel is an ultra-high strength steel with high strength and toughness, good hardenability, no obvious temper brittleness, small deformation during quenching, high fatigue limit and multiple impact resistance after quenching and tempering. Good impact toughness at low temperature, high creep strength and enduring strength at high temperature.The steel usually uses surface quenching after quenching and tempering as the heat treatment plan.

Our company has advanced cold and warm extrusion technology, specializing in the development and manufacturing of automobiles, motorcycles, various machinery and electric tools, and mining equipment accessories.

Cold extruded automobile engagement sleeves, universal joints, cylinder blocks, flanges, front axles, hollow shafts, transmission shafts, gear shafts, various types of valve seats, pistons for hydraulic presses, high-pressure pipe plugs, rollers for mining equipment, guides Wheels, various steel feet and aluminum alloy products for high-voltage power grids, etc. The above blanks and finished products can be provided.

Various planetary gears, sun gears, ring gears, output side plates, spline shafts, transmission shafts, gear plates, spline sleeves, drum bodies and various special-shaped parts of cold-extrusion automobiles and electric winches. The above-mentioned finished and semi-finished products are all Can provide.

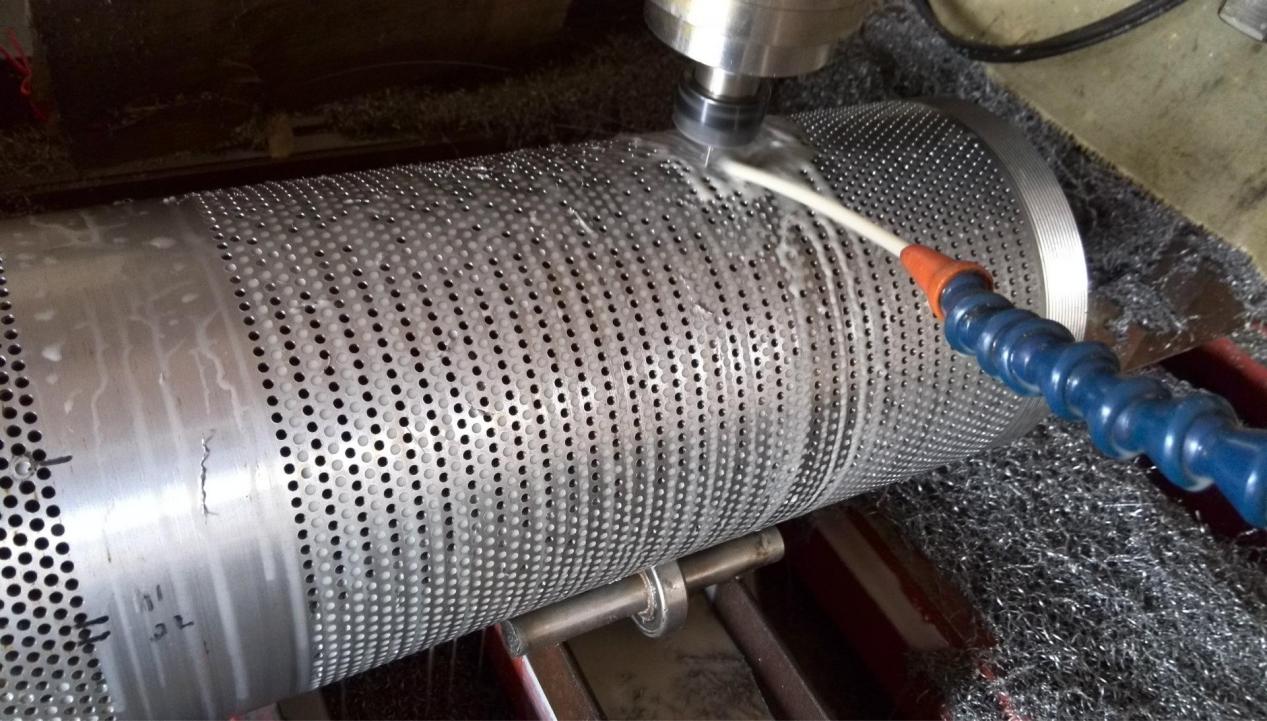

Drill Hole

Smoke Exhaust Pipe

Product detail pictures:

Related Product Guide:

CHINA STEEL NEWS – REPORT ON CHINA’S STEEL MARKET – China Steel prices continue to rising.

China’s steel products have added 23 new tax numbers to cancel export tax rebates. – Will be implemented on August 1, 2021.

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Best Price on Cold Drawn Tube Process - Steel Pipe Processing – XUANZE , The product will supply to all over the world, such as: Kuwait, Serbia, Myanmar, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.