Heat-treated Steelpipe

Heat treatment refers to the double heat treatment method of quenching and high temperature tempering. Its purpose is to make the workpiece have good comprehensive mechanical properties. High temperature tempering refers to tempering at 500-650 ℃. Most of the hot parts work under the action of relatively large dynamic load. They bear the effects of tension, compression, bending, torsion or shear. Some surfaces also have friction, which requires certain wear resistance. In short, the parts work under various compound stresses. This kind of parts are mainly structural parts of various machines and mechanisms, such as shafts, connecting rods, studs, gears, etc., which are widely used in machine tools, automobiles, tractors and other manufacturing industries. Especially for large parts in heavy machinery manufacturing, heat treatment is used more. Therefore, heat treatment plays an important role in heat treatment. In mechanical products, due to the different stress conditions, the required performance is not the same. Generally speaking, all kinds of hot parts should have excellent comprehensive mechanical properties, that is, the proper combination of high strength and high toughness to ensure the long-term smooth operation of parts.

Heat treatment of steel pipe is one of the important processes in mechanical manufacturing. Compared with other processing technologies, heat treatment generally does not change the shape and chemical composition of the whole workpiece, but endows or improves the performance of the workpiece by changing the internal microstructure or chemical composition of the workpiece surface. Its characteristic is to improve the internal quality of the workpiece, which is generally not visible to the naked eye. In order to make the steel pipe have the required mechanical, physical and chemical properties, the heat treatment process is often necessary in addition to the reasonable selection of materials and various forming processes. Steel is the most widely used material in mechanical industry. The microstructure of steel is complex and can be controlled by heat treatment. In addition, the mechanical, physical and chemical properties of aluminum, copper, magnesium, titanium and their alloys can also be changed by heat treatment to obtain different service properties.

Product name: Heat-treated steel pipe

Place of Origin: Shandong, China

Carbon content control range: 0.30~0.50%.

Quenched and tempered steel: ASTM 1045, ASTM 5140, ASTM 4140

Heat treatment steel classification:

● Carbon quenched and tempered steel

● Alloy quenched and tempered steel

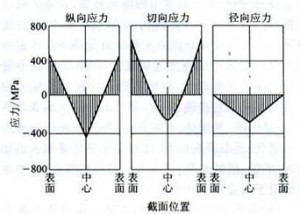

Hardness adjustment:

● Center-surface

● Surface-center

In order to obtain good overall performance of heat-treated steel, the carbon content is generally controlled at 0.30%-0.50%.

Quenched and tempered steel: ASTM 1045, ASTM 5140, ASTM 4140

Types:pipe and bare

Heat treatment steel bar Sizes:

Outer diameter: 1/2”-24”

Wall thickness: SCH10-XXS

Length: 5.8-12Meter

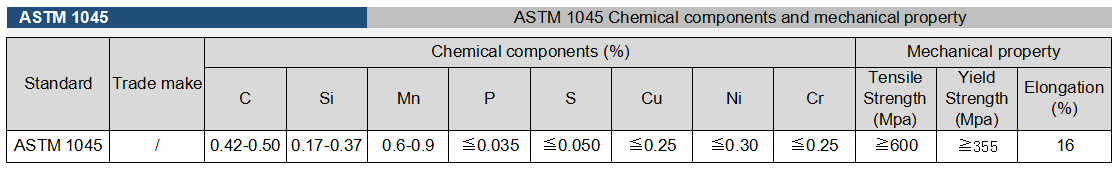

ASTM 1045 Chemical components and mechanical property:

ASTM 1045 HEAT TREATMENT RQUEST:

Hardness of 1045 steel after quenching: HRC 56-59

Heating temperature: 560~600℃.

Heat temperature hardness requirements: HRC 22-30

Heat treatment purpose: Comprehensive mechanical properties.

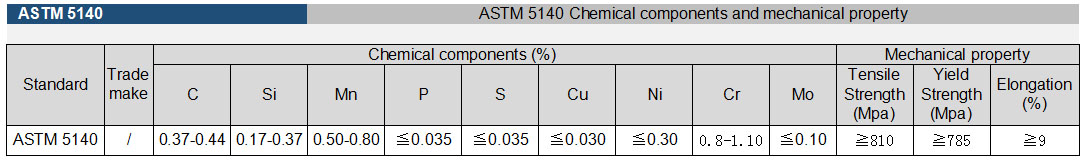

ASTM 5140 Chemical components and mechanical property:

DETECT:

APPLICATION:

After quenching and tempering at medium temperature, it is used to manufacture parts that can withstand high load, impact and medium speed, such as gears, main shafts, oil pump rotors, sliders, collars, etc.

ASTM 5140 GEARS

ASTM 5140 MAIN SHAFTS