1.HEAVY WALL SEAMLESS STEEL PIPE

Heavy-walled seamless pipes are definitely better than ordinary pipes. The first is that the seamless structure of the pipe wall and the pipe body are very smooth, and the second is that the stainless steel is resistant to high temperatures and cold, and will not deform. Or twisted, thick-walled seamless pipes play a big role in the process of modern industrialization. Oil pipelines must use this thick-walled seamless pipe as a transportation tool. Because of the high quality, no oil leakage accidents will occur. Thick-walled seamless pipe is a necessary material tool for many oil companies.

2.PRECISION SEAMLESS STEEL PIPE

Precision seamless pipe is a high-precision steel pipe material processed by cold drawing or hot rolling. Precision seamless steel pipes are mainly used to produce pneumatic or hydraulic components, such as air cylinders or oil cylinders, which are all made of seamless pipes. It can be used to manufacture mechanical structures, hydraulic equipment, and auto parts.When the bending and torsion strength is the same, the precision seamless steel pipe is lighter. It is a kind of economical section steel and is widely used in the manufacture of structural parts and mechanical parts. While inheriting the advantages of seamless steel pipes, precision steel pipes also have some of their own characteristics. The use of precision manufacturing of ring parts can increase the utilization rate of materials, simplify the manufacturing process, and save materials and processing man-hours. For example, rolling bearing rings, jack sleeves, etc., have been widely manufactured with precision steel pipes. The popularization and application of precision seamless pipes is of great significance for saving steel, improving processing efficiency, and reducing processing procedures or equipment investment. It can save costs and processing man-hours, increase production volume and material utilization, and at the same time help improve product quality and reduce costs. It is of great significance to improve economic efficiency.

3.SPECIAL SHAPE SEAMLESS STEEL PIPE

Special shape steel pipe can be divided into oval shaped steel tube, triangular shaped steel tube, hexagonal shaped steel tube, the diamond shaped steel tube, octagonal shaped steel tube, semicircle deformed steel circle, etc.We can customize according to your drawings.Special-shaped seamless steel pipes are widely used in various structural parts, tools and mechanical parts. Compared with round tubes, special-shaped tubes generally have larger moments of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce structural weight and save steel.

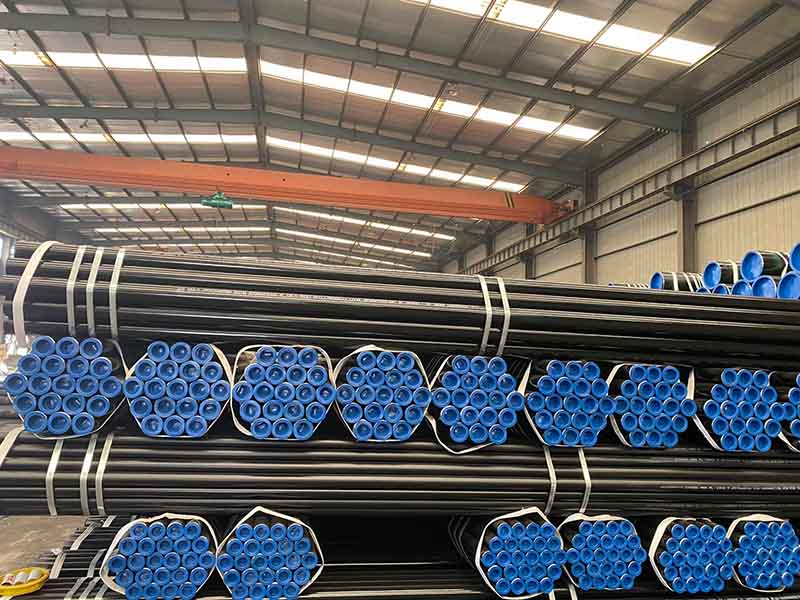

4.API5LGR.B BLACK PAINTED LINE PIPE

API5LGR.B Line pipes are used to transport the oil, steam, and water extracted from the ground to the petroleum and natural gas industrial enterprises through line pipes. Line pipes include seamless pipes and welded steel pipes. The pipe ends have flat ends, threaded ends and socket ends; its connection The method is welding, coupling connection, socket connection, etc. A large number of pipelines are used to transport fluids, such as oil, natural gas, water, gas, steam, etc. In addition, when the bending and torsion strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also often used to produce various conventional weapons, barrels, and shells.

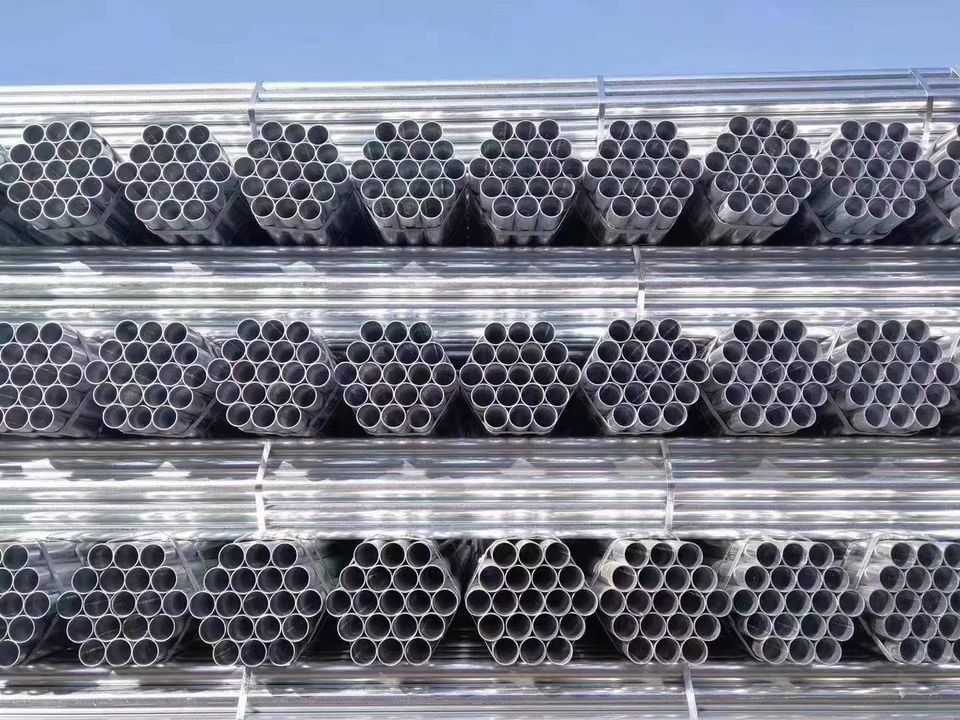

5.GALVANEZED SEAMLESS STEEL PIPE

Galvanizing can increase the corrosion resistance of the steel pipe and prolong its service life. Galvanized pipe has a wide range of uses. In addition to line pipes for conveying water, gas, oil and other general low-pressure fluids, it is also used as oil well pipes and oil pipes in the petroleum industry, especially offshore oilfields, as well as oil heaters and condensation for chemical coking equipment. Pipes for coolers, coal-distilled wash oil exchangers, pipe piles for trestle bridges, and pipes for supporting frames in mine tunnels

Post time: Dec-08-2020