China Wholesale Sa 179 Seamless Tube Factories - Hydraulic Cylinder Seamless Pipe – XUANZE

China Wholesale Sa 179 Seamless Tube Factories - Hydraulic Cylinder Seamless Pipe – XUANZE Detail:

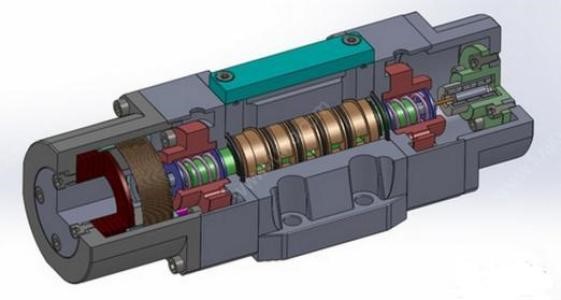

Hydraulic cylinder seamless steel pipe is suitable for oil, hydraulic cylinder, mechanical processing, thick wall pipeline, chemical industry, electric power, boiler industry, high temperature, low temperature and corrosion resistance seamless steel pipe, and it is suitable for petroleum, aviation, smelting, food, water conservancy, electric power, chemical industry, chemical fiber, medical machinery and other industries.

Due to the surface residual compressive stress left in the surface layer of hydraulic cylinder, it is helpful to close the surface micro cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the generation or expansion of fatigue crack can be delayed, thus the fatigue strength of quilted tube can be improved. Through rolling forming, a layer of cold work hardening layer is formed on the rolling surface, which reduces the elasticity of contact surface of grinding pair.

Therefore, the wear resistance of the inner wall of the quilting tube is improved and the burn caused by grinding is avoided. After rolling, the reduction of surface roughness can improve the matching properties.

Rolling is a kind of chip free machining, which uses the plastic deformation of metal at room temperature to flatten the micro unevenness of the workpiece surface, so as to change the surface structure, mechanical properties, shape and size. Therefore, this method can achieve both finishing and strengthening at the same time, which is impossible for grinding.

No matter what kind of processing method is used, there will always be fine uneven tool marks on the surface of the parts, resulting in staggered peaks and valleys,

Rolling processing principle: it is a kind of pressure finishing, which uses the cold plastic characteristics of metal at room temperature, and applies certain pressure to the surface of the workpiece by rolling tools to make the metal on the surface of the workpiece produce plastic flow and fill in the original residual low concave trough, so as to reduce the surface roughness of the workpiece. Due to the plastic deformation of the rolled surface metal, the surface structure is cold hardened and the grains become fine, forming a dense fibrous layer and forming a residual stress layer. The hardness and strength of the surface are improved, so the wear resistance, corrosion resistance and compatibility of the workpiece surface are improved. Rolling is a cutting free plastic processing method.

Advantages of seamless steel pipe for hydraulic cylinder:

1. The surface roughness can reach RA ≤ 0.08 & micro; M.

2. The ovality can be ≤ 0.01mm.

3. The surface hardness is increased to eliminate the stress deformation, and the hardness is increased HV ≥ 4 °

4. After machining, there is residual stress layer, and the fatigue strength is increased by 30%.

5. It can improve the matching quality, reduce wear and prolong the service life of parts, but the processing cost of parts is reduced.

Improve the fatigue strength of the quilted pipe.

Improve the wear resistance of the inner wall of the quilted pipe.

1. The surface roughness can reach RA ≤ 0.08 & micro; M.

2. The ovality can be ≤ 0.01mm.

3. The surface hardness is increased to eliminate the stress deformation, and the hardness is increased HV ≥ 4 °

4. After machining, there is residual stress layer, and the fatigue strength is increased by 30%.

5. It can improve the matching quality, reduce wear and prolong the service life of parts, but the processing cost of parts is reduced.

Used for fluids, boilers, high pressure seamless pipes for boilers, high pressure for fertilizer equipment, geological drilling, oil drilling, oil cracking, oil drill collars, automobile axles, ships.

Compared with mechanical transmission and electric transmission, hydraulic transmission has the following advantages:

1. Various components of hydraulic transmission can be conveniently and flexibly arranged according to needs.

2. Light weight, small size, small movement inertia and fast reaction speed.

3. Convenient operation and control, which can realize stepless speed regulation in a wide range (speed regulation range up to 2000:1).

4. Overload protection can be realized automatically.

5. Generally, mineral oil is used as the working medium, the relative moving surface can be lubricated by itself, and the service life is long;

6. It is easy to realize linear motion/

7. It is easy to realize the automation of the machine. When the electro-hydraulic combined control is adopted, not only a higher degree of automatic control process can be realized, but also remote control can be realized.

Product detail pictures:

Related Product Guide:

Iron ore rose by as much as 113%! Australia’s GDP surpasses Brazil for the first time in 25 years!

The PPI of China’s ferrous metal smelting and rolling processing industry rose 12.0% year-on-year from January to February.

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for China Wholesale Sa 179 Seamless Tube Factories - Hydraulic Cylinder Seamless Pipe – XUANZE , The product will supply to all over the world, such as: Australia, Singapore, Costa Rica, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.