Leading Manufacturer for Seamless Hydraulic Tubing - Heavy Wall Steel Pipe – XUANZE

Leading Manufacturer for Seamless Hydraulic Tubing - Heavy Wall Steel Pipe – XUANZE Detail:

The production and manufacturing process of heavy wall seamless steel pipe can be divided into cold drawing, cold rolling, hot rolling and hot expansion. The materials of steel pipe are 10, 20, 35 and 45, which are called ordinary steel pipe. According to the application, it can be divided into structural seamless steel pipe, seamless steel pipe for transportation, seamless steel pipe for boiler, high-pressure seamless steel pipe for boiler, high-pressure seamless steel pipe for chemical fertilizer equipment and seamless steel for geological drilling Pipe; seamless steel pipe for oil drilling; seamless steel pipe for petroleum cracking; seamless steel pipe for ship; cold drawn and cold-rolled precision seamless steel pipe; various alloy pipes. Seamless steel pipe is mainly used in mechanical processing, coal mine, hydraulic steel, etc.

The raw material of thick wall seamless steel pipe is round tube blank. The round tube blank is cut by cutting machine, and the billet with a growth of about 1 m is sent to the furnace by conveyor belt for heating. The billet is heated in a furnace at about 1200 degrees Celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key problem. After the round tube is discharged from the furnace, it needs to pass through the pressure piercer. Generally, the more common piercer is the cone roll piercer. This kind of piercer has high production efficiency, good product quality, large perforation diameter expansion, and can wear a variety of steel grades. After piercing, the round billet is successively rolled by three roll cross rolling, continuous rolling or extrusion. After extrusion, the tube should be removed for sizing. The sizing machine rotates the cone drill bit into the steel blank at high speed to form a steel pipe.

The inner diameter of the steel pipe is determined by the outer diameter length of the drill bit of the sizing machine. After sizing, the steel pipe enters the cooling tower and is cooled by water spray. After cooling, the steel pipe will be straightened. After straightening, the steel pipe is sent to the metal flaw detector (or hydraulic test) by conveyor belt for internal flaw detection. If there are cracks and bubbles inside the steel pipe, it will be detected. After the quality inspection of steel pipes, strict manual selection is required. After the quality inspection of the steel pipe, the number, specification and production batch number shall be sprayed with paint. It is hoisted into the warehouse by crane.

HEAVY WALL SEAMLESS STEEL PIPE

Wear resisting Self lubrication High chemical sability Various size and type

The production and manufacturing process of heavy wall seamless steel pipe can be divided into cold drawing, cold rolling, hot rolling and hot expansion.

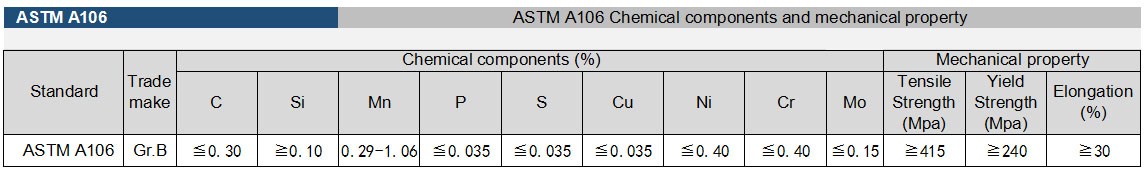

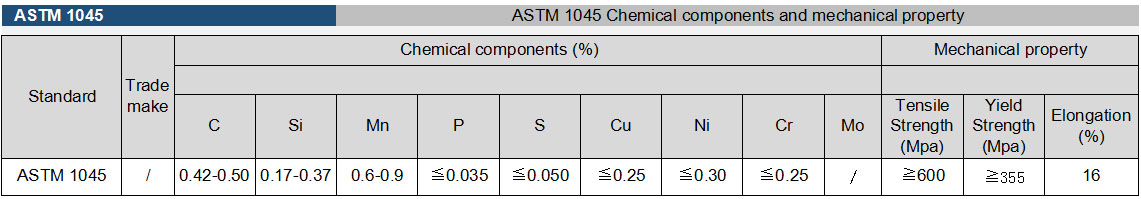

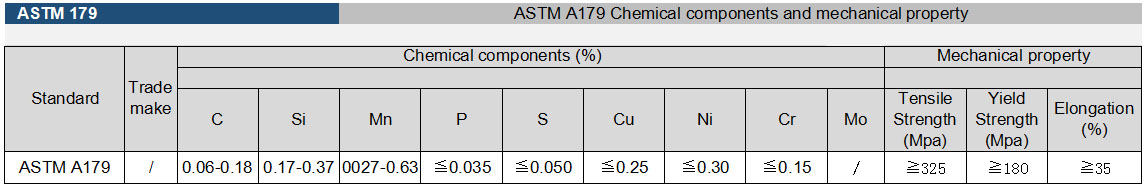

The materials of steel pipe are ASTM 179, A106Gr.B, 1035 and 1045, which are called ordinary carbon steel pipe.

The materials of steel pipe are ST52 ,ASTM 5140,4140,4135,12XMФ, which are called ordinary alloy steel pipe.

ASTM A106Gr.B chemical composition and mechanical properties

ASTM 1045 chemical composition and mechanical properties

ASTM A179 chemical composition and mechanical properties

Uniform thickness

ALLOY HEAVY SEAMLESS STEEL PIPE

Product detail pictures:

Related Product Guide:

Chinese steel mills have intensively raised prices, raising billets by ¥40 per ton – Steel prices continued their upward trend.

CHINA STEEL NEWS – REPORT ON CHINA’S STEEL MARKET – China Steel prices continue to rising.

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for Leading Manufacturer for Seamless Hydraulic Tubing - Heavy Wall Steel Pipe – XUANZE , The product will supply to all over the world, such as: Monaco, Venezuela, Nigeria, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.