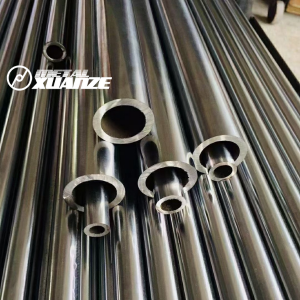

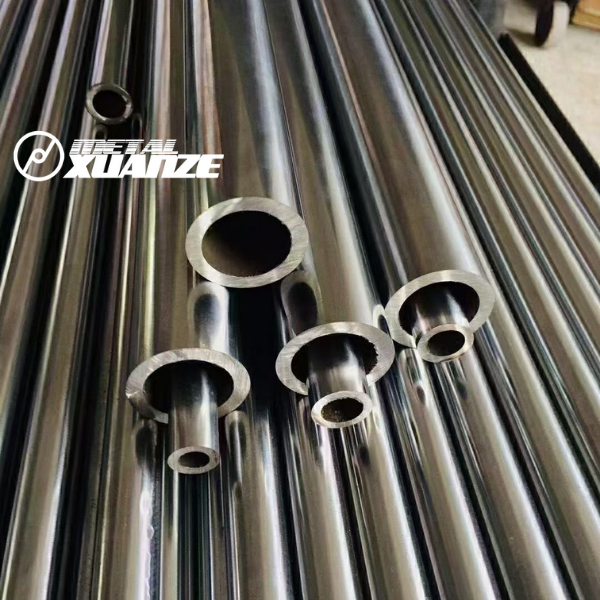

COLD DRAWN SEAMLESS STEEL PIPE

PRODUCT DETAILS

STOCKED SIZE RANGE:

- 1.000″ to 10.000″ O.D. with 0.100″ to 1.500″ Wall Thickness

- Stocked in 16.000′ – 29.000′ random lengths (cut to length available)

MATERIAL:

- CARBON: ASTM A106GR.B,A179/192,S45C

- ALLOY:ST52,5140,4140,4135.

MANUFACTURING PROCESS:

CDS(cold drawn steel) seamless tube and pipe is produced by piercing hot billets and subsequent rolling which reduces their diameter and elongates them. This material is then passed through a die and over a mandrel plug to produce an accurate size and gauge which is the essence of the cold drawing process.

BENEFITS OF COLD DRAWN SEAMLESS TUBING:

HIGHER STRENGTH & HARDNESS PROPERTIES

- Cold drawing increases the strength of the tube therefore making it very suitable for safety and performance critical applications.

SIZE ACCURACY

- Due to the nature of the manufacturing process drawn tubes can be manufactured to close dimensional tolerances, achieving consistent diameter and thicknesses throughout.

ENHANCED APPEARANCE

- Cold drawn seamless tube usually has a shinier look with no weld lines increasing the aesthetics of the products in which it is incorporated.

UNIFORM MICRO-STRUCTURE

- Due to the cold drawing process, CDS has excellent micro-structure uniformity and consistency.

EASIER TO MACHINE

- Due to the superior strength and hardness, it produces a better machined surface and therefore a better-looking component.

SUPERIOR FINISH IN SUBSEQUENT MANIPULATIONS

- As cold drawn tubes have a glossier, no-seam finish they also produce better end products from processes such as dipping, etching and anodizing.

APPLICATIONS BY INDUSTRY:

CONSTRUCTION & HEAVY EQUIPMENT

- Augers

- Chassis

- Crane Boom Lacings

- Cylinders

- Hydraulics

- Shafts

- Struts

- Transmission Shafts

AGRICULTURE

- Hydraulic Cylinders

- Machinery Frames & Cages

- Augers

- Booms

- Chassis

- Shafts

- Spacers

- Bushings

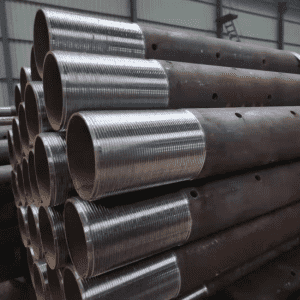

INFRASTRUCTURE

- Columns

- Rollers

- Lift Components

FLUID HANDLING

- Engine Assemblies

- Pumps

- Other Components Which Liquids Will Flow (Especially at High Speeds)

MACHINERY

- Numerous Internal Machine Components

- Pumps

- Hydraulic Components

- Frames

- Industrial Lift Components

- Tool Extensions

- Material

Write your message here and send it to us